Essential Tips for Working with Sheet Metal for Beginners?

Sheet metal work is an essential skill in various industries. According to a report by Research and Markets, the global sheet metal fabrication market is expected to reach over $300 billion by 2027. This growth highlights the importance of mastering this craft. Beginners often find themselves overwhelmed by technical aspects. However, with the right approach, learning can be effective.

Understanding sheet metal properties is crucial. Different materials, such as aluminum and stainless steel, have unique characteristics. A beginner should grasp how these materials behave under stress. Experience teaches that the right tools can make a big difference. Invest in quality shears, brakes, and other equipment to enhance your work.

Mistakes are part of the learning process. It's common to misjudge measurements or make improper cuts. Reflecting on these errors can lead to better outcomes. Moreover, joining workshops or engaging with online communities can provide support. Connecting with others in the industry helps refine skills and improve confidence. Embrace the journey of working with sheet metal. Each step, even the imperfect ones, leads to growth and proficiency.

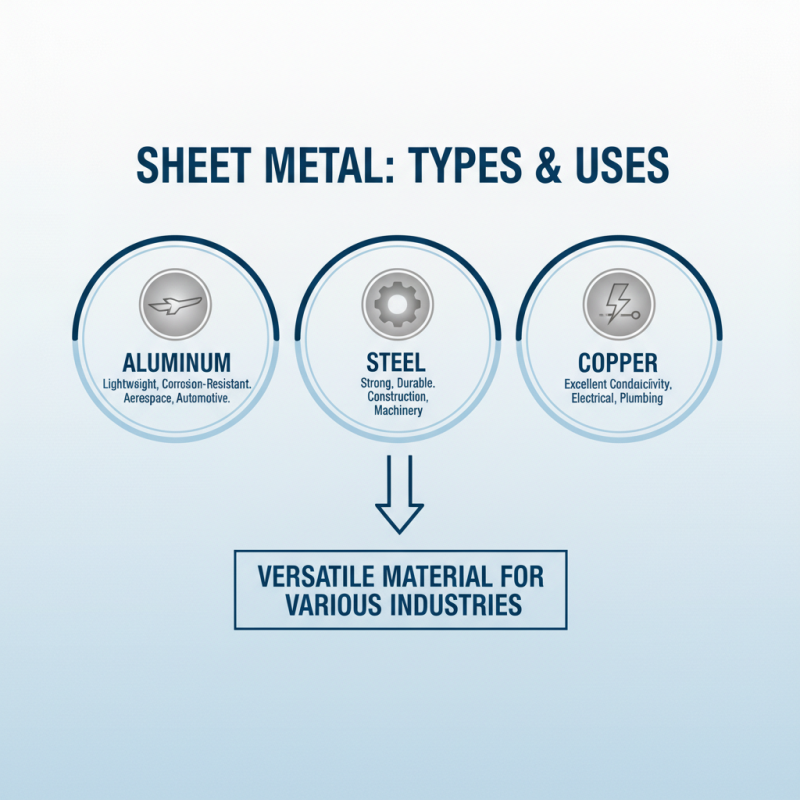

Understanding Sheet Metal: Types and Properties

Sheet metal is a versatile material used in various industries. It comes in several types, each with unique properties. Common types include aluminum, steel, and copper. Aluminum is lightweight and resistant to corrosion. Steel offers strength and durability, making it ideal for structural applications. Copper is excellent for electrical conductivity but can be expensive.

Understanding the properties is vital for beginners. The thickness of sheet metal is measured in gauges. Lower gauge numbers mean thicker material. For example, a 20-gauge steel sheet is thicker than a 24-gauge one. This distinction is crucial when considering structural integrity. A report by the Steel Market Development Institute highlights that the demand for lightweight metals in various sectors is rising by 3% annually.

However, working with sheet metal can challenge beginners. The process requires precision. Small mistakes can lead to wasted materials and increased costs. Accurate measurements and clean cuts are essential. Lack of attention to detail can result in subpar products. Reflecting on these common pitfalls can help beginners improve their skills quickly.

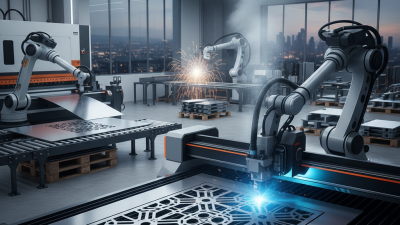

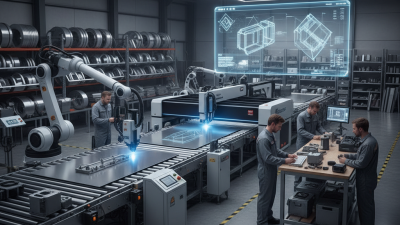

Essential Tools for Sheet Metal Fabrication

When beginning your journey in sheet metal fabrication, having the right tools is crucial. Commonly recommended tools include snips, hammers, and shears. According to industry reports, over 40% of new metalworkers cite inadequate tools as a significant barrier to success. Investing in quality equipment can significantly enhance your efficiency and results.

For precise cuts, use aviation snips. They are versatile and easy to handle. Don't forget safety gear, like gloves and goggles. It's essential to protect yourself while working with sharp materials. Many beginners overlook safety, leading to small injuries that create setbacks. Remember, safety first.

Another important tool is the metal brake. It helps you bend sheets accurately. Mastering this tool allows for creativity in your designs. Yet, many novice users struggle to get the bends right. Practice is vital. A good tip is to start with scrap pieces before working on valuable materials. This will save you time and frustration. The right set of tools and practice can lead to beautiful results in your projects.

Basic Techniques for Cutting and Shaping Sheet Metal

Cutting and shaping sheet metal can be challenging for beginners. However, mastering basic techniques is essential for any metalworking project. According to the Fabricators & Manufacturers Association, nearly 50% of industry professionals cite proper cutting techniques as vital for achieving clean edges and precise dimensions. Using a straight edge and measuring correctly can help avoid mistakes.

When it comes to cutting methods, a few options stand out. Shears are great for straight cuts, while snips are useful for curves. Plasma cutters offer precision for thicker materials, but they come with a learning curve. Beginners often struggle with tool settings, which can lead to cleanup issues later. A consistent pace during cutting is also critical; going too fast may result in jagged edges.

Shaping the metal can be equally tricky. Hammering requires practice to produce smooth bends without creating weak points. For intricate shapes, a hammer form can help maintain consistency. Remember, it's okay to make errors; learning from them is part of the process. The American Welding Society emphasizes that over 60% of new fabricators experience initial failures. Reflection on these challenges can lead to better techniques down the road.

Safety Precautions When Working with Sheet Metal

When working with sheet metal, safety should always be the top priority. Protective gear is essential. Wear safety goggles to shield your eyes from metal shards. Gloves can protect your hands, but choose them wisely. They shouldn't be too thick, or you might lose dexterity. Steel-toed boots prevent injuries from heavy materials falling.

Be aware of your surroundings. Sheet metal can have sharp edges. Inspect your workspace before starting. Clear away unnecessary items. Proper ventilation is vital when using tools that create dust or fumes. A well-lit area helps you spot hazards early.

Take breaks to avoid fatigue. Tiredness can lead to accidents. Reflect on your actions as you work. Did you skip any steps? Rushing can compromise your safety. Slow down and double-check your processes. Mistakes can be costly, both in time and health. Safety is not just a habit; it’s a mindset that every beginner should embrace.

Tips for Finishing and Joining Sheet Metal Projects

When finishing and joining sheet metal, attention to detail is crucial. Begin by cleaning the metal surfaces thoroughly. Dust, oil, or rust can affect bonding quality. Use a wire brush or sandpaper to prepare the edges of the metal you intend to join. A smooth surface allows for a better fit and stronger welds or seams.

Next, choose the right joining method based on your project requirements. Options include welding, soldering, or using rivets. Each technique has its advantages and challenges. For instance, welding creates a strong bond but requires practice and proper safety gear. Soldering might be easier for beginners but may not provide the same strength. Experimenting with different methods can lead to better results, but don't hesitate to seek guidance.

Finally, understand that imperfections can arise. Your first few attempts might not be perfect. Gaps and uneven joins are common. Review your work critically. Learn from these mistakes to improve your skills. With practice, you'll find techniques that work best for you. Embrace the learning process as part of creating beautiful projects.

Essential Tips for Working with Sheet Metal for Beginners

| Tip | Description | Tools Required | Common Techniques |

|---|---|---|---|

| Safety First | Always wear safety goggles and gloves when working with sheet metal to prevent injury. | Safety goggles, gloves | N/A |

| Measure Twice, Cut Once | Make precise measurements to avoid material waste and ensure a perfect fit. | Tape measure, straight edge | Cutting |

| Use the Right Tools | Select tools specifically designed for sheet metal to achieve the best results. | Tin snips, sheet metal brake | Bending, cutting |

| Practice Join Techniques | Familiarize yourself with welding and riveting methods to join pieces effectively. | Welder, rivet gun | Welding, riveting |

| Finishing Touches | Smooth edges and surfaces to avoid sharp points and improve aesthetics. | File, sandpaper | Sanding, filing |

Related Posts

-

Top 10 Best Sheet Metal Fabrication Techniques for Your Industry Needs

-

The Future of Sheet Metal in 2025 Trends Innovations and Best Practices

-

How to Start Sheet Metal Fabrication in 2026?

-

Top 10 Advantages of Sheet Metal Fabrication for Your Projects?

-

How to Choose the Best Laser Cutter for Your DIY Projects in 2023

-

Common Issues Faced in CNC Cutting Operations