How to Start Sheet Metal Fabrication in 2026?

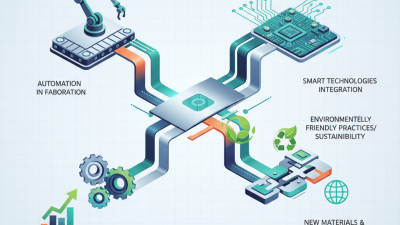

Starting a venture in sheet metal fabrication can be exciting yet challenging in 2026. The industry is evolving with new technologies. However, the fundamental concepts remain crucial for success. You must understand the basics, like cutting, bending, and assembling metal sheets.

Equipment selection is vital in this field. Investing in high-quality tools impacts production efficiency and product quality. It's essential to stay updated with trends and advancements. New materials and techniques can enhance your capabilities.

Though the path seems clear, obstacles may arise. Skill gaps can exist among your team. Additionally, competition in the market is fierce. Reflecting on these challenges is important. Adapting and learning from setbacks will shape your business in the long run.

Understanding the Basics of Sheet Metal Fabrication

Sheet metal fabrication involves transforming flat sheets of metal into functional products. This process requires a good understanding of various techniques. Cutting, bending, and welding are some basic methods. Each of these techniques has specific applications. Cutting can be done using shears or lasers. Bending requires proper tooling to achieve accurate angles. Welding unites metal pieces and demands precision.

Getting started in this field can be challenging. Many new fabricators struggle with understanding material properties. For example, different metals behave differently under heat or stress. A mistake in choosing materials can lead to project failures. Additionally, the learning curve in mastering machinery is steep. Many people find themselves overwhelmed by the complexity of tools and processes. Trial and error is common at this stage.

Thinking about sustainability is also crucial. The initial focus might be on profit, but long-term success requires eco-friendly practices. Recycling scrap metal can reduce costs. Engaging in community resources can provide support and education. Reflecting on these aspects can lead to a more successful and responsible fabrication journey. Adapting to changes and learning continuously will shape your path in sheet metal fabrication.

How to Start Sheet Metal Fabrication in 2026? - Understanding the Basics of Sheet Metal Fabrication

| Aspect | Detail |

|---|---|

| Industry Overview | Sheet metal fabrication is essential for various industries, including automotive, aerospace, and construction. |

| Basic Processes | Processes include cutting, bending, welding, and assembling metal sheets. |

| Materials Used | Common materials are steel, aluminum, copper, and stainless steel. |

| Required Tools | Tools include laser cutters, CNC machines, and bending machines. |

| Safety Measures | Personal protective equipment (PPE) and proper training are vital to ensure safety. |

| Business Considerations | Consider market research, startup costs, and competition in your area. |

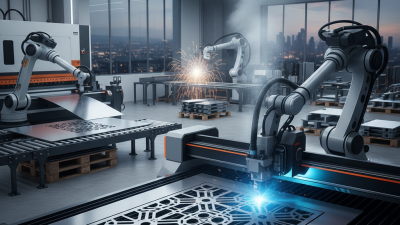

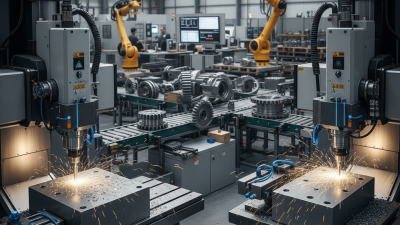

Key Tools and Equipment Needed for Sheet Metal Fabrication

Starting a sheet metal fabrication business requires understanding essential tools and equipment. A recent industry report indicates that the global sheet metal fabrication market is projected to reach $267 billion by 2027. This growth highlights the increasing demand for metal products across various sectors.

Key tools include a shearing machine, which cuts sheets into desired shapes. These machines can vary in size and capacity. An industrial-grade shear can cost thousands. Additionally, a brake press forms sheet metal into angles or bends. Technological advancements in CNC technology are increasing precision but require operators to adapt. Laser cutting systems also represent a significant investment, often exceeding $100,000.

Safety equipment cannot be overlooked. Gloves, goggles, and ear protection are essential. Neglecting safety can lead to serious injuries. A clean workspace with proper ventilation is vital, too. During the setup phase, many newcomers ignore operational costs, which can strain early finances. Investing in high-quality tools can improve efficiency, but it is essential to balance this with budget constraints. Many find this challenging and must reassess their priorities.

Essential Skills for Successful Fabrication in 2026

In 2026, acquiring essential skills for sheet metal fabrication will define success in the industry. Technical abilities like welding, cutting, and bending are fundamental. According to a recent industry report, over 70% of employers now seek workers proficient in advanced fabrication technologies. Mastering these skills is crucial, yet many new entrants struggle to keep pace with rapid technological changes.

Understanding CAD software is another vital skill. Nearly 65% of sheet metal shops incorporate digital design tools for efficiency. However, many potential fabricators are not adequately trained in these technologies. This gap creates a significant barrier to entry. Furthermore, hands-on experience is often overlooked. Practical skills acquired through apprenticeships or vocational programs can enhance one’s job prospects significantly.

Moreover, the need for problem-solving skills cannot be overstated. Fabricators frequently face unexpected challenges. Flexibility and creativity in approaching these issues can set one apart in this competitive field. A report highlighted that only 40% of workers feel prepared to address such challenges effectively. This indicates a crucial area for growth in training programs. Developing these essential skills will help ensure successful careers in sheet metal fabrication as 2026 approaches.

Selecting the Right Materials for Sheet Metal Projects

Selecting the right materials is crucial for sheet metal fabrication. Different projects require different metals. Aluminum, for instance, is lightweight and corrosion-resistant. It’s ideal for complex designs and quick projects. However, it may not hold up under heavy stress.

Steel offers strength and durability. It’s perfect for structural components. Stainless steel, while resistant to rust, can be more difficult to work with. It might not be the best choice for beginners. Consider your project requirements carefully.

Copper is another option, known for its excellent conductivity. It’s often used in electrical applications. However, it can be pricey and may require special handling during fabrication. Each material has its pros and cons. It's important to weigh them against your specific needs. Remember, experimenting with materials can lead to unexpected outcomes. Sometimes, a choice might not yield the expected results. That’s part of the learning curve.

Material Selection for Sheet Metal Fabrication in 2026

This chart illustrates the percentage popularity of various materials used for sheet metal fabrication projects in 2026. Aluminum remains the most popular choice, followed by steel and stainless steel.

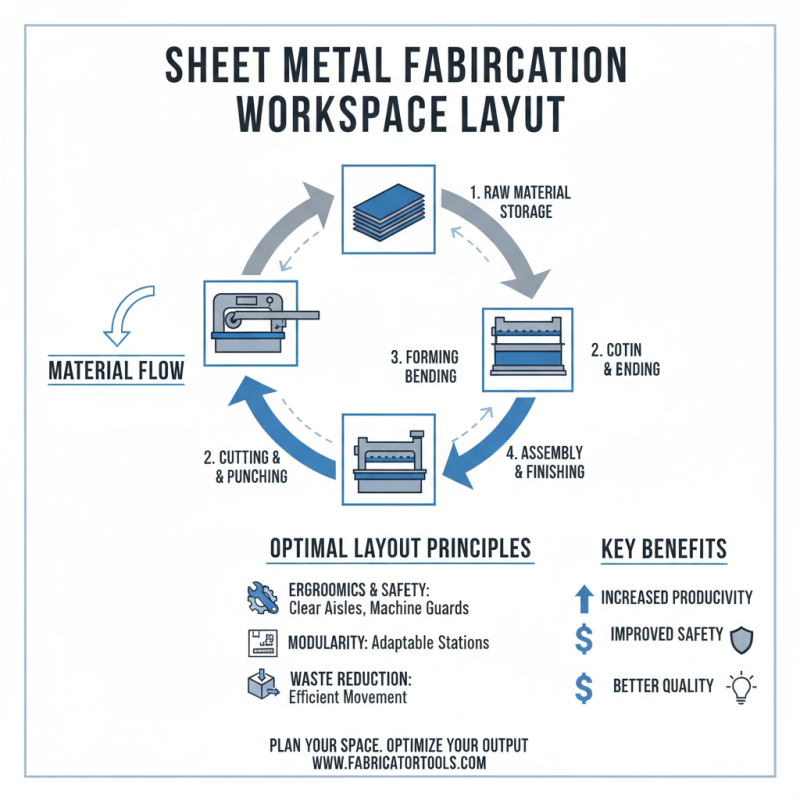

Setting Up Your Fabrication Workspace Efficiently

Starting a sheet metal fabrication workspace requires careful planning. The layout and organization of your space can significantly impact your productivity. Consider the flow of materials. Your workspace should facilitate easy movement from one station to another.

**Tip:** Use a dedicated area for cutting and shaping. This zone must be well-lit and equipped with essential tools. Incorporate storage solutions like racks or shelves to declutter. Keeping your tools organized saves time.

Don't forget to create a safety zone. Metal can be sharp and dangerous. Ensure you have protective gear easily accessible. Install safety signage around the workspace. Regularly remind yourself to maintain a clean environment.

**Tip:** A daily cleanup routine is crucial. It helps prevent accidents and keeps the workspace efficient. Make it a habit to inspect your tools. A broken tool can cause delays and injuries. Being proactive about maintenance is essential for a successful fabrication operation.

Related Posts

-

Top 10 Best Sheet Metal Fabrication Techniques for Your Industry Needs

-

Why CNC Metal Cutting is Essential for Modern Manufacturing Efficiency

-

The Future of Sheet Metal in 2025 Trends Innovations and Best Practices

-

Innovative Tube Laser Cutting Solutions for Enhanced Manufacturing Efficiency

-

How to Choose the Best CO2 Laser Cutter for Your Projects and Needs

-

5 Best Metal Laser Cutter Techniques for Precision Cutting