How to Improve CNC Metal Cutting Efficiency for Better Results?

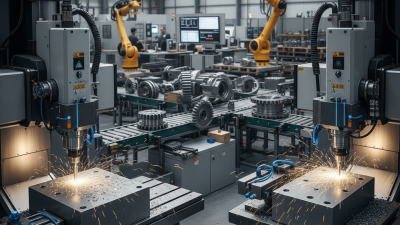

CNC metal cutting is a critical process in manufacturing. Reports indicate that improving CNC metal cutting efficiency can lead to significant cost savings. For instance, a well-optimized CNC system can reduce operational costs by up to 20%. However, many companies still struggle with inefficiencies that hinder productivity.

One common issue is tool wear, which can drastically affect output quality. According to recent studies, up to 30% of production time is lost due to tool-related problems. This highlights a crucial area for improvement. Companies need to invest in monitoring tools and training to enhance performance. Additionally, adopting advanced technologies can improve CNC metal cutting efficiency.

The integration of automation and advanced analytics can pinpoint issues before they escalate. Such measures can transition manual processes into streamlined operations. Overall, while many industries benefit from advancements in CNC metal cutting, there remains a gap that companies must address. The quest for improvement is ongoing and often filled with reflection on past inefficiencies.

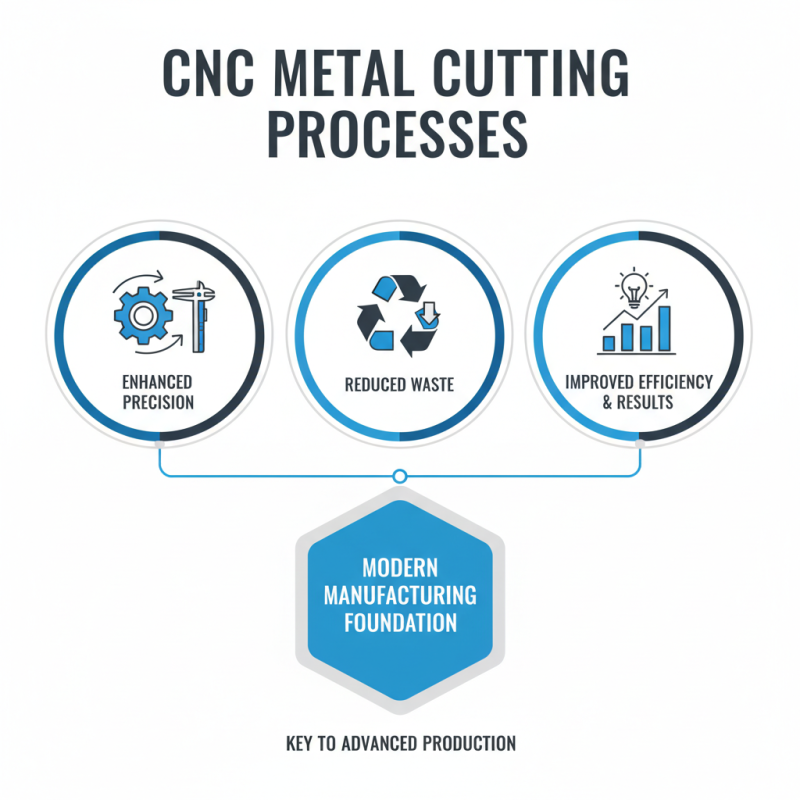

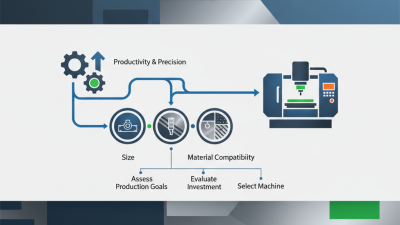

Understanding CNC Metal Cutting Processes and Their Importance

CNC metal cutting processes are vital in modern manufacturing. They enhance precision and reduce waste significantly. Understanding these processes is key to improving efficiency and achieving better results.

Tips: Always ensure your tools are sharp. Dull tools can lead to inaccuracies and increased wear. Regular maintenance can prevent unexpected breakdowns. Adjust feed rates according to the material type being cut. An incorrect feed rate can result in poor surface finish and longer cutting times.

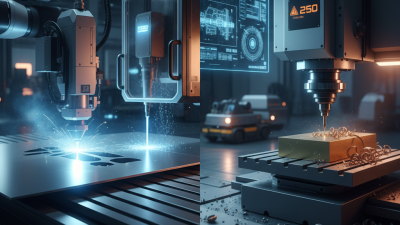

It's important to analyze the cutting parameters. Overlooking factors like speed and depth can diminish performance. Integrating automation can also streamline the process. However, automation requires careful planning and may lead to initial challenges. Balancing technology and human oversight is essential for optimal efficiency.

Factors Affecting CNC Metal Cutting Efficiency

CNC metal cutting efficiency is influenced by various factors. The type of material being cut plays a crucial role. For example, harder metals like titanium require slower cutting speeds. In contrast, softer materials like aluminum can be cut quickly. According to a report from the International Journal of Advanced Manufacturing Technology, optimizing feed rates and speeds can improve efficiency by up to 20%.

Tool wear is another significant factor. As tools wear down, cutting becomes less effective. A study from the University of Michigan found that worn tools can reduce cutting efficiency by as much as 30%. Regular inspections and adjustments are essential to maintain tool performance. Operators must be skilled in recognizing signs of wear and responding promptly.

Machine calibration also matters. A misaligned machine can lead to inefficient cuts, wasting both time and resources. Data from the Journal of Materials Processing Technology indicates that poorly calibrated machines contribute to increased scrap rates. Regular maintenance checks are vital. Each of these factors highlights the importance of a proactive approach in optimizing CNC metal cutting processes.

How to Improve CNC Metal Cutting Efficiency

Techniques to Optimize CNC Machine Settings for Precision

Optimizing CNC machine settings is crucial for enhancing metal cutting efficiency. Precision in speed, feed rate, and tooling can significantly impact the quality of the cut and the lifespan of tools. According to a study by the Society of Manufacturing Engineers, optimizing feed rates can improve production efficiency by 20-30%. This is substantial in high-volume manufacturing environments.

When adjusting settings, consider the material type and thickness. For aluminum, a higher feed rate often yields faster results. However, pushing limits can cause tool wear. It's a fine balance. Some operators may overlook the need for regular tool inspections, which can lead to inconsistent results and increased costs in the long run.

Moreover, utilizing advanced software for simulations can help in visualizing cutting paths. This technique aids in identifying potential issues before actual cutting begins. Yet, many still rely solely on traditional methods. Data from recent market analysis indicates that only 40% of CNC shops are implementing smart technology. This gap illustrates an area for improvement that can lead to significant advancements in efficiency.

Tools and Materials for Enhanced CNC Cutting Performance

CNC metal cutting efficiency relies heavily on the selection of tools and materials. High-quality cutting tools can significantly reduce cutting time. For instance, using carbide tools has been shown to improve tool life by up to 50%. This longevity translates into fewer tool changes, which enhances overall machining efficiency. However, it's essential to regularly assess the tool's condition. Dull tools can lead to increased friction and heat, potentially damaging both the workpiece and the machine.

Material choice also plays a crucial role in cutting efficiency. Aluminum and stainless steel, for example, require different cutting speeds and feeds. A study highlighted that a proper feed rate can boost productivity by 30%. Yet, many operators fail to optimize these parameters. Moreover, the selection of cutting inserts must match the specific material being cut. Incorrect insert choice can lead to premature tool wear and reduced performance. Therefore, continuous learning and adaptation to the specific job requirements are vital for improved results.

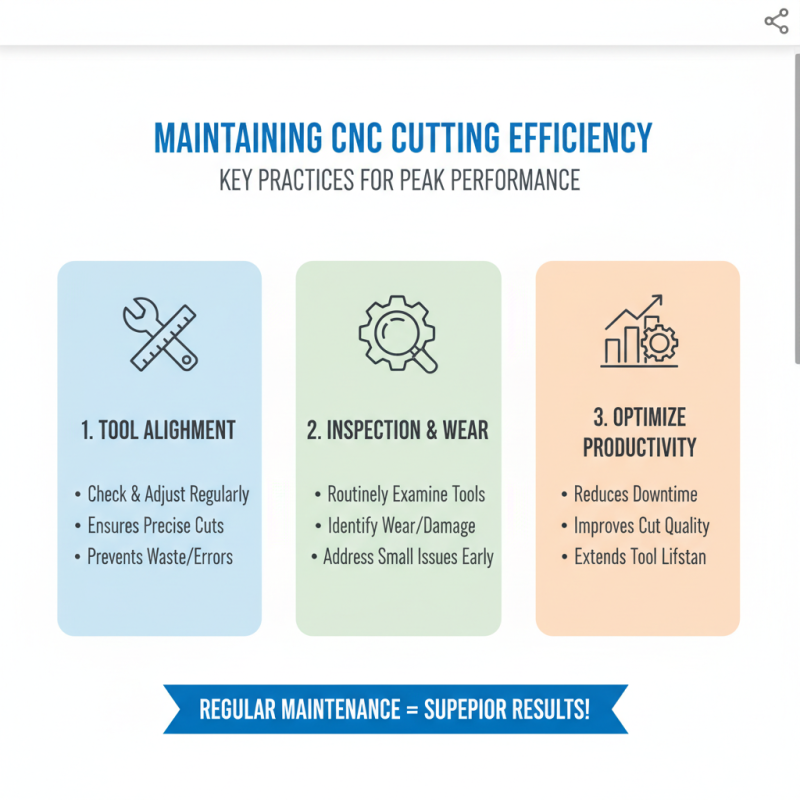

Maintenance Practices for Sustaining High CNC Cutting Efficiency

Regular maintenance is crucial for sustaining high CNC cutting efficiency. Checking and adjusting tool alignment ensures precise cuts. Misalignment can lead to poor quality and increased waste. Regular inspection of tools and components helps identify wear and tear. Small issues can escalate if unnoticed, impacting overall productivity.

Lubrication is another key aspect. Keeping parts well-lubricated minimizes friction. This reduces heat and prevents damage during operation. However, over-lubrication can attract dirt and debris. Finding the right balance requires attention and regular adjustments. Scheduling maintenance intervals can help in minimizing downtime and boosting cutting efficiency.

Monitoring machine settings is vital. Parameters such as speed and feed need to match the material used. An incorrect setup can lead to inefficiencies and subpar results. Operators should be trained to make adjustments on the fly. This adaptability can enhance workflow and ensure better outcomes. Maintaining cleanliness around the machine is essential too. Dust and chips can cause significant disruptions in performance. Regular cleaning routines prevent unexpected breakdowns and maintain cutting quality.

Related Posts

-

What is the Process Behind CNC Metal Cutting Technology

-

2026 Best CNC Metal Cutting Techniques for Precision and Efficiency?

-

10 Essential Tips for Optimizing Your CNC Metal Cutting Process

-

Why CNC Metal Cutting is Essential for Modern Manufacturing Efficiency

-

How to Choose the Best CNC Metal Cutting Techniques for Your Manufacturing Needs

-

How to Choose the Right CNC Milling Machine for Your Projects