What is a CNC milling machine and how does it work?

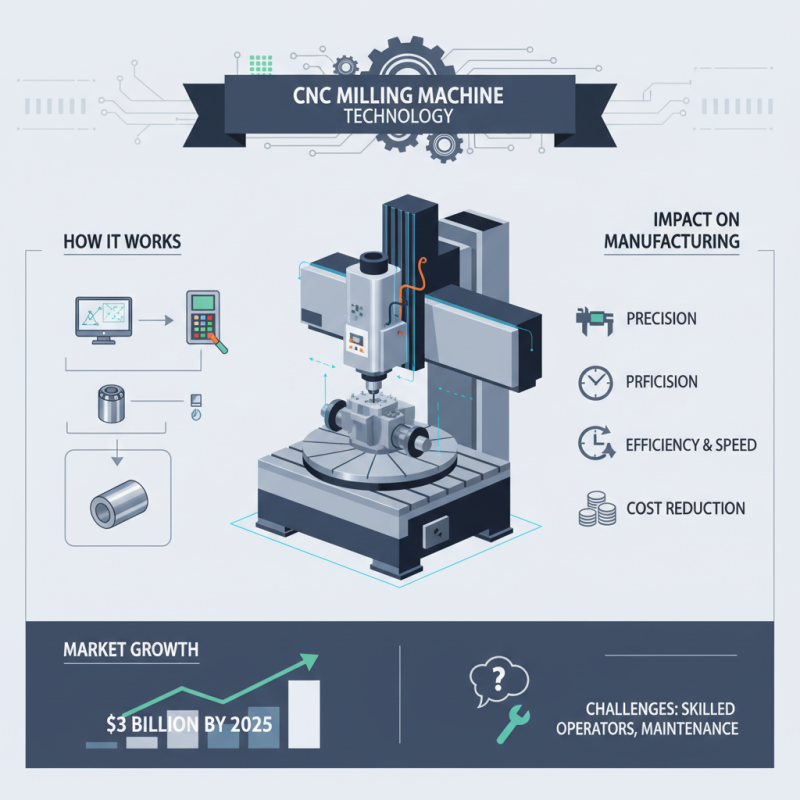

CNC milling machines represent a significant advancement in manufacturing technology. They are essential for producing precise parts across various industries. According to a recent market analysis by Technavio, the global CNC milling machine market is projected to grow by over $3 billion by 2025. This growth reflects increasing demand for high-accuracy machined components.

John Smith, a leading expert in CNC technology, emphasizes the importance of efficiency in this field. He stated, "CNC milling machines enable manufacturers to improve precision while reducing time and labor costs." This highlights the critical role these machines play in enhancing production capabilities.

Understanding how CNC milling machines operate is vital for leveraging their potential. These machines use computer-controlled tools to remove material from a workpiece. They can produce complex shapes with high accuracy. However, challenges remain, such as the need for skilled operators and maintenance concerns. New users often grapple with the steep learning curve. Despite these challenges, the impact of CNC milling machines on modern manufacturing is undeniable.

What is a CNC Milling Machine? Definition and Overview

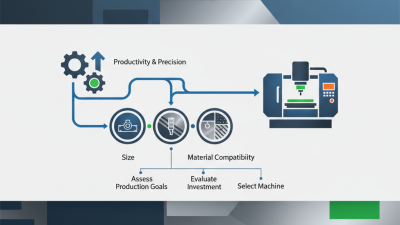

CNC milling machines are essential in modern manufacturing. They automate the cutting and shaping of materials, offering precision. The term CNC stands for Computer Numerical Control. This technology allows for intricate designs with minimal human intervention. According to a recent industry report, the global CNC milling machine market was valued at around $5 billion in 2022, with a projected growth rate of 6.5% annually.

These machines can handle various materials, including metals, plastics, and composites. They can create complex parts with high repeatability. Users input specific commands, and the machine translates these into movements. However, the complexity of CNC programming can be daunting. Many operators face a steep learning curve. In fact, a survey indicated that 30% of CNC users struggle with programming and setup.

Operational efficiency is often challenged. Machine downtime can occur due to maintenance or technical issues. This is especially true if the workforce lacks adequate training. Reports highlight that nearly 25% of companies experience unexpected breakdowns annually. Ensuring proper handling and continuous education on CNC technology is vital for maximizing performance and productivity.

What is a CNC Milling Machine and How Does it Work?

| Feature | Description |

|---|---|

| Definition | A CNC milling machine is a computer-controlled tool that cuts and shapes materials such as metal, plastic, and wood. |

| Functionality | It operates by moving a rotating cutting tool along multiple axes to remove material from a workpiece. |

| Types | Common types include vertical, horizontal, and universal CNC milling machines. |

| Applications | Used in various industries for manufacturing parts in automotive, aerospace, and consumer goods sectors. |

| Advantages | High precision, repeatability, a variety of shapes, and reduced waste material. |

| Limitations | High initial setup costs, complexity in programming, and maintenance requirements. |

| Future Trends | Incorporation of AI and machine learning for improved automation and workflow optimization. |

Key Components of CNC Milling Machines and Their Functions

CNC milling machines are crucial in modern manufacturing. They operate with precision using computer numerical control. Key components include the spindle, a vital part that rotates the cutting tool. The spindle's speed can reach thousands of RPM, allowing for efficient cutting of materials like metal and plastic.

Another essential component is the milling table. It holds the workpiece in place. Table size varies, affecting the size of parts that can be manufactured. In many industries, a larger table can increase productivity and reduce setup time. Additionally, the feed mechanism guides the tool. It determines the depth of cut and speed, influencing the overall efficiency.

Tips: Regular maintenance of the spindle can prolong its life. Clean and lubricate it often. Ensure the table is level before starting any milling process. This avoids inaccuracies in the machining process. Operators should understand the machine’s limits. Overloading can lead to damage or imprecise operations. Balancing workload is key for optimal performance.

How CNC Milling Machines Operate: Step-by-Step Process

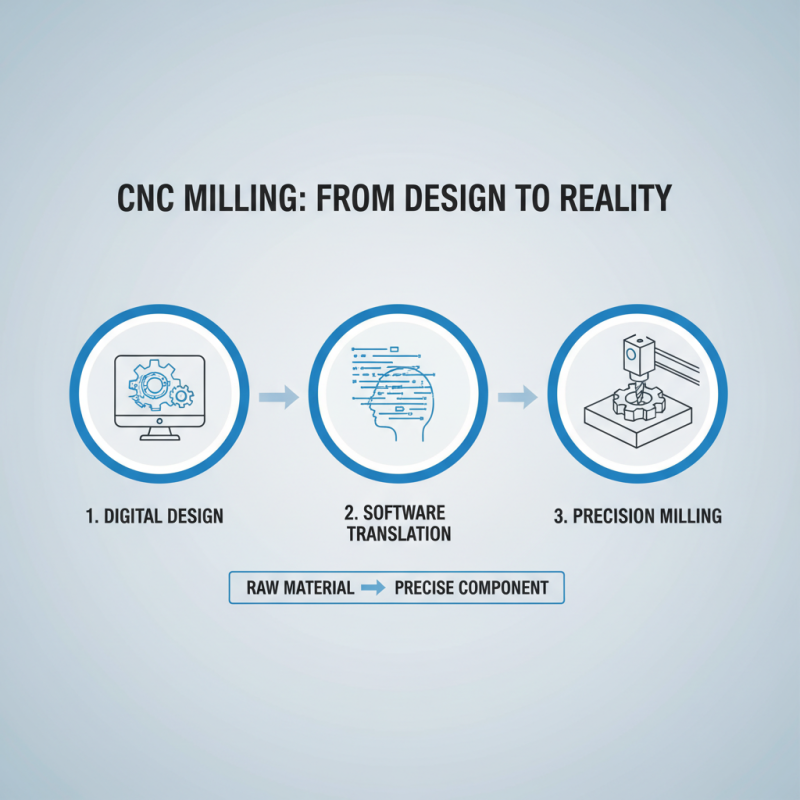

CNC milling machines are fascinating tools that transform raw materials into precise components. Understanding how they operate can demystify their complexity. The process begins with a digital design. This design is input into the computer software. The software then translates the design into machine language, which guides the milling machine’s movements.

Once the design is uploaded, the operator secures the material on the machine bed. The machine uses various cutting tools. These tools rotate at high speeds, removing material from the workpiece. It is crucial to select the right tool for the job. A poor choice can result in subpar finishes. Operators must monitor the process closely to ensure accuracy.

During the milling process, feedback is essential. The machine needs real-time adjustments to optimize performance. Sometimes, unexpected issues arise, such as tool wear or misalignment. These problems require quick problem-solving skills. Operators must reflect on each session to improve future outcomes. Each project is an opportunity to learn and refine techniques.

Common Materials Processed by CNC Milling Machines in Industry

CNC milling machines are versatile tools used in many industries. They can process a wide range of materials. Common materials include metals, plastics, and wood. Each material presents its own challenges. For example, aluminum is lightweight but can be tricky to work with. Proper feed rates are crucial.

[Acrylic Image]

Plastics such as acrylic and PVC are popular in prototyping. They are easy to machine, but require careful handling. Acrylic can melt if overheated, and that can ruin a project. Wood is another common choice. It’s natural and easy to cut, yet it varies widely in density. Some wood types can splinter, which is an issue.

The choice of material influences production. It's vital to align the machine settings with the material properties. Mistakes can happen. These can lead to wasted time and resources. Continuous learning is essential in mastering the CNC milling process. Recognizing the unique traits of materials helps in achieving better outcomes.

Applications and Benefits of CNC Milling in Manufacturing Sectors

CNC milling machines are essential in modern manufacturing. They operate using computer numerical control to manage the machining process effectively. This technology allows for high precision and repeatability, making it suitable for various applications.

In manufacturing sectors like aerospace and automotive, CNC milling enhances productivity. It can create complex shapes and components that would be challenging using traditional methods. Parts produced are often lighter and more efficient. CNC milling also reduces waste materials, leading to cost savings.

Tips: Always ensure proper calibration of your CNC machine. Regular maintenance can extend its lifespan immensely. Additionally, training operators on new software can lead to significant efficiency gains.

However, the reliance on technology may cause issues if not monitored. Machine errors or programming mistakes can lead to costly delays. It is crucial to consistently evaluate the processes in place. Adapting to new developments may require initial investments and time. Embracing these challenges ensures long-term benefits in production quality and efficiency.

Related Posts

-

10 Essential Tips for Using a CNC Milling Machine Effectively?

-

Top 5 CNC Milling Machines of 2025: Unmatched Precision and Performance

-

Understanding the Innovations Behind CNC Metal Cutting Techniques

-

How to Choose the Right CNC Milling Machine for Your Projects

-

10 Essential Tips for Optimizing Your CNC Metal Cutting Process

-

How to Choose the Best CNC Metal Cutting Techniques for Your Manufacturing Needs