Why is CNC Metal Cutting Essential for Precision Manufacturing?

In today's fast-paced manufacturing environment, CNC metal cutting has become a cornerstone for precision. According to a recent report from MarketsandMarkets, the CNC machining market is projected to reach $100 billion by 2025, reflecting a compound annual growth rate (CAGR) of over 6%. This growth highlights the increasing reliance on advanced technology for accuracy and efficiency.

CNC metal cutting offers unparalleled precision. This technique minimizes human error while enhancing the consistency of products. For instance, parts manufactured using CNC processes can maintain tolerances as tight as 0.001 inches. However, achieving such precision is not without challenges. The initial costs of CNC machines can be high, and skilled operators are necessary to maximize their potential.

Moreover, while CNC metal cutting streamlines production, it also requires ongoing maintenance and calibration. Neglecting these aspects can lead to inefficiencies and defects. Overall, CNC metal cutting is essential for industries that demand high-quality, precise parts, and it continues to redefine manufacturing capabilities.

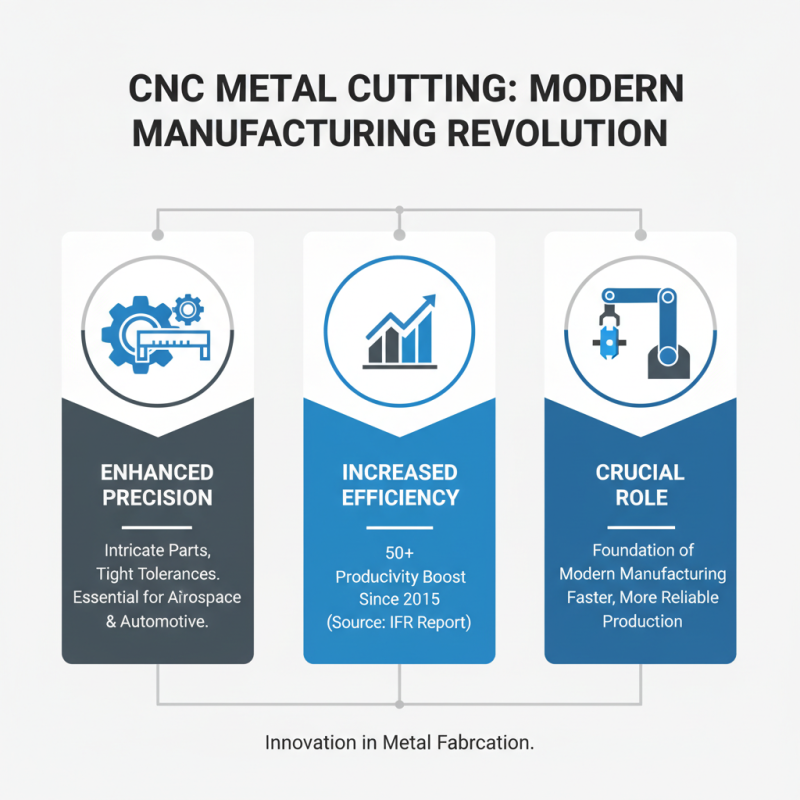

The Role of CNC Metal Cutting in Modern Manufacturing

CNC metal cutting plays a crucial role in modern manufacturing. It enhances precision and efficiency in production processes. According to a report by the International Federation of Robotics, the use of CNC machines has increased productivity by over 50% in many sectors since 2015. This technology allows manufacturers to produce intricate parts with tight tolerances, essential in industries like aerospace and automotive.

However, achieving this level of precision presents challenges. Operators must be trained to handle the complexities of CNC systems. Data from the National Institute of Standards and Technology shows that 30% of manufacturing errors stem from operator mistakes. Regular maintenance is also vital. Neglecting this can lead to costly downtime. In fact, a survey by Deloitte reveals that 22% of manufacturers experience significant delays due to equipment failures.

Another consideration is material waste. While CNC cutting minimizes scrap, it still produces waste byproducts. The Environmental Protection Agency estimates that metal fabrication contributes to 14% of industrial waste. Companies must address this issue to improve sustainability. Balancing efficiency, training, and waste management remains a continuous challenge in the evolving landscape of precision manufacturing.

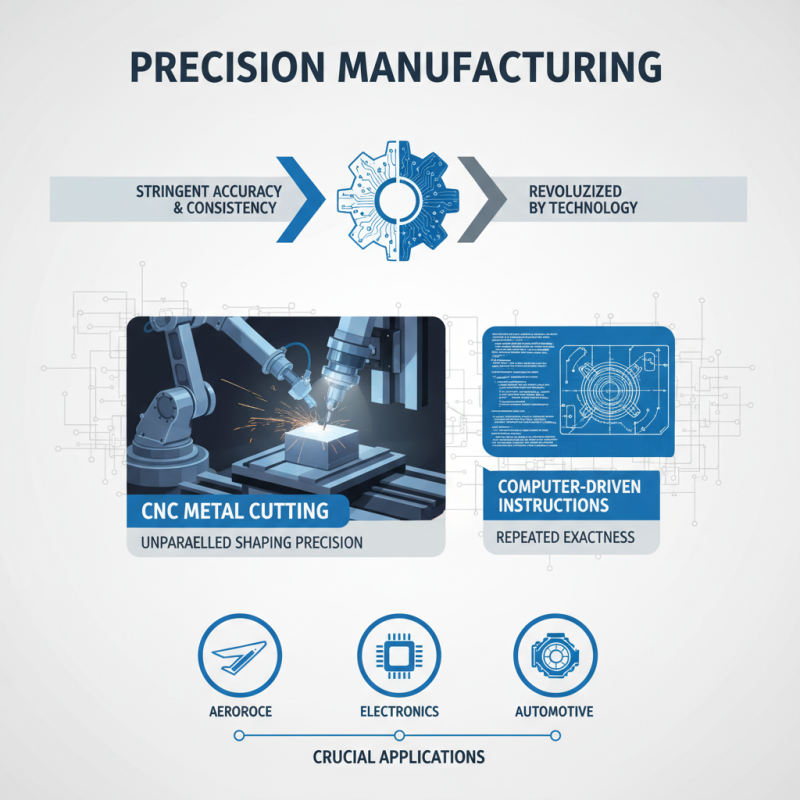

Understanding Precision Requirements in Manufacturing Processes

Precision manufacturing relies heavily on stringent requirements for accuracy and consistency. The advent of CNC metal cutting technology revolutionized this field. It provides unparalleled precision in shaping metal parts, which is crucial for various applications. Each cut made by a CNC machine is driven by detailed computer instructions. This allows for repeated exactness in production.

In precision manufacturing, small deviations can lead to significant issues. A fraction of a millimeter can disrupt the functionality of complex systems. Therefore, refining precision requirements is an ongoing challenge. Some businesses may underestimate the skill and attention needed in the process. This can lead to costly errors. Crafting metal parts with CNC cutting requires constant monitoring and adjustment.

Many manufacturers still struggle with integrating new technologies. While CNC machines can enhance speed and precision, they also present a learning curve. Workers must adapt to new software and methods. Mistakes can occur during this transition, highlighting the need for continuous training. Precision isn’t just about the machines; it’s also about the people operating them. The synergy between technology and skill is where the true challenge lies.

Advantages of CNC Metal Cutting Over Traditional Methods

CNC metal cutting has transformed the manufacturing landscape. It offers numerous advantages over traditional methods. Precision and accuracy are paramount in modern manufacturing. CNC machines cut metal to exact specifications, minimizing errors and waste. Traditional machining can often involve human error, leading to inconsistencies.

Speed is another crucial advantage. CNC machines operate quickly and can work continuously. They reduce production times significantly compared to manual methods. Operators can set up multiple jobs, so machines can run unattended. This efficiency allows for greater output without compromising quality.

Tips: When implementing CNC technology, ensure proper training for your operators. Understand the machine's limitations. Regular maintenance is vital to avoid costly downtime. Always evaluate job designs for optimization before cutting.

CNC machines also excel in complex geometries. Traditional methods struggle with intricate designs. CNC allows for tailored solutions that meet specific project needs. It’s essential to reflect on material costs and machine wear. Balancing precision with overall costs can lead to more profitable manufacturing.

Applications of CNC Metal Cutting in Various Industries

CNC metal cutting is widely used across various industries. It offers precision in creating intricate parts. Automotive manufacturing frequently relies on this technology. Car parts require exact specifications. Mistakes in cutting can lead to costly recalls. Therefore, the need for precision is critical.

Aerospace is another sector benefiting from CNC cutting. Components for aircraft must meet strict standards. Each piece must perform flawlessly under extreme conditions. Small errors can compromise safety. CNC technology helps achieve the necessary accuracy.

In the medical field, CNC cutting plays a vital role. Surgical instruments need to be precise and reliable. Any deviation might affect a procedure's success. This technology allows for complex designs that enhance usability. Each industry demonstrates how CNC metal cutting shapes the future of manufacturing.

Applications of CNC Metal Cutting in Various Industries

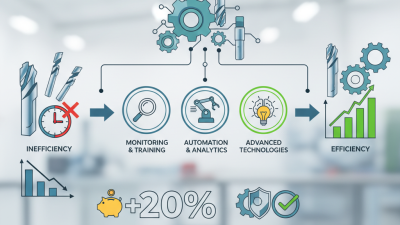

Future Trends in CNC Metal Cutting Technology and its Impact on Precision

As CNC metal cutting technology advances, its influence on precision manufacturing becomes more significant. The future holds exciting developments. Automation is one key area poised for growth. New machines are integrating advanced robotics, enhancing accuracy and reducing human error. Yet, there are challenges. Operators require training to handle these sophisticated machines effectively.

Another trend is the rise of adaptive machining. This allows machines to adjust their parameters on the fly. Such adjustments lead to optimal cutting conditions. However, it can be difficult to implement. Manufacturers need to ensure the right software and tools are in place. Constant monitoring is essential.

Sustainability is also gaining traction. Eco-friendly materials and processes are becoming necessary. Companies face pressure to minimize waste. This shift may not be easy. It requires significant investment in research and development. Yet, embracing these trends can lead to a competitive edge. The journey toward innovation in CNC metal cutting is filled with opportunities and obstacles.

Why is CNC Metal Cutting Essential for Precision Manufacturing? - Future Trends in CNC Metal Cutting Technology and its Impact on Precision

| Aspect | Current Trends | Impact on Precision Manufacturing |

|---|---|---|

| Automation | Increased use of automated CNC machines | Enhanced efficiency and reduced human error |

| Software Integration | Advanced CAD/CAM software | Improved design accuracy and workflow |

| Material Innovation | Development of new alloys and composites | Wider application for precision requirements |

| 3D Printing Integration | Combining CNC machining with 3D printing | Greater design flexibility and reduced waste |

| Sustainability Focus | Shift towards eco-friendly machining practices | Minimized environmental impact in manufacturing |

Related Posts

-

How to Improve CNC Metal Cutting Efficiency for Better Results?

-

What is the Process Behind CNC Metal Cutting Technology

-

2026 Best CNC Metal Cutting Techniques for Precision and Efficiency?

-

10 Essential Tips for Optimizing Your CNC Metal Cutting Process

-

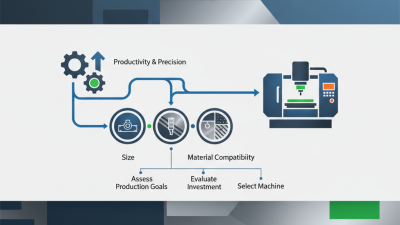

How to Choose the Right CNC Milling Machine for Your Projects

-

10 Best CNC Metal Cutting Technologies That Boost Efficiency by 30 Percent