Best Metal Laser Cutter for Precision and Efficiency?

In the fast-evolving world of manufacturing, precision is paramount. A well-regarded expert in the field, Dr. John Smith, emphasizes, "The right metal laser cutter can define the success of a project." As industries strive for efficiency and accuracy, selecting the best metal laser cutter becomes critical. There are various factors to consider, from cutting speed to material compatibility.

Metal laser cutters have transformed how we approach metal fabrication. These machines offer speed and precision that traditional methods cannot match. However, it is essential to recognize that not all options are equal. Some models may fall short in performance or reliability, leading to production delays.

Additionally, the initial cost of these advanced tools can be daunting. Companies must weigh the investment against expected returns. Ultimately, the choice of the best metal laser cutter should align with the specific needs of the business. Striking a balance between quality and cost-effectiveness remains a challenge for many manufacturers aiming for excellence in their operations.

Overview of Metal Laser Cutting Technology

Metal laser cutting technology has transformed the manufacturing landscape. This method employs high-powered lasers to cut through various metals with remarkable precision. Reports indicate that laser cutting can achieve an accuracy of ±0.1 mm. Industries are increasingly adopting this technology for its efficiency and clean cuts.

The process involves focusing a laser beam onto the metal surface. The heat generated melts or vaporizes the material, allowing for intricate designs with smooth edges. In fact, the speed of cutting can reach up to 20 meters per minute. However, the energy consumption can be surprisingly high, leading to increased operational costs. Companies must evaluate if the efficiency justifies the expenses.

Tips: Before investing in a metal laser cutter, assess your specific needs. Understand the types of metal you will work with. Consider the thickness and the required tolerances. Ensure your team has proper training to minimize errors.

Another point for thought: the technology is not without limitations. Certain alloys may reflect laser energy, causing cuts to be less effective. Research suggests that understanding the interaction between the laser and the material is crucial for optimal outcomes. Adjusting settings may be necessary to avoid imperfections. Always anticipate challenges during projects.

Key Features to Look for in a Metal Laser Cutter

When selecting a metal laser cutter, precision is essential. Look for machines that offer high-resolution cutting capabilities. A good cutter should achieve tight tolerances. Laser focus is crucial; a well-focused beam prevents rough edges.

Efficiency is equally important. Choose a cutter with a fast cutting speed. Time is money in manufacturing. A compact design saves space but might limit material size. Consider the cutter’s capability to handle various metals. Different materials require specific settings.

User-friendly controls can also enhance your experience. Intuitive software eases operation and reduces errors. However, training may still be necessary. A machine might offer advanced features, yet users could find them complex. These intricacies often call for practice and patience.

Always evaluate your needs against the cutter's capabilities. Balancing precision and efficiency is key.

Top Brands and Models for Precision Cutting

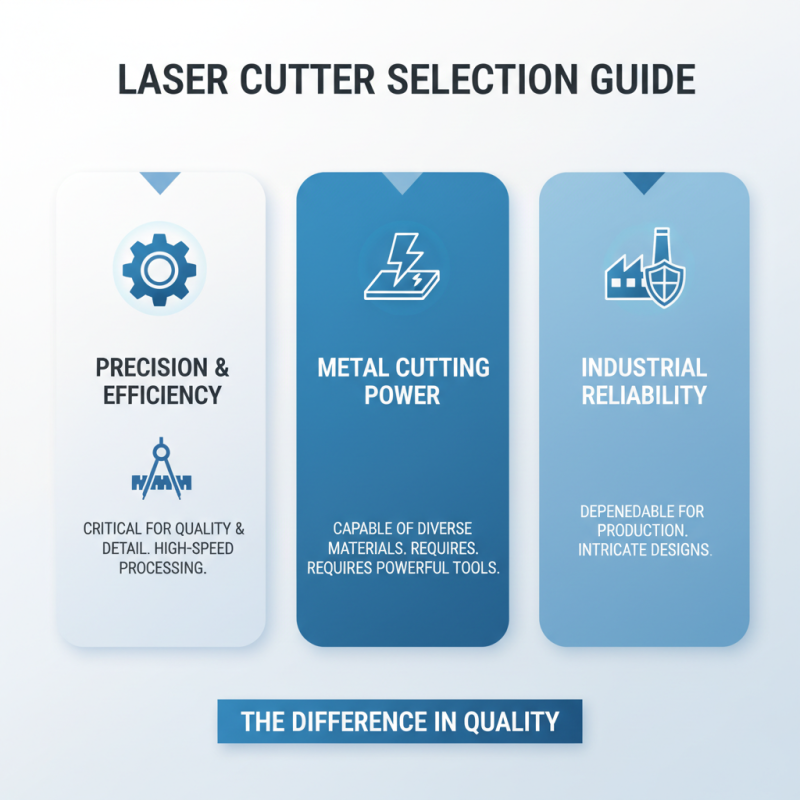

When selecting a laser cutter, precision and efficiency are critical. Cutting metal requires powerful tools capable of handling different materials. Many industries depend on reliable machines for intricate designs and high-speed processing. A reliable laser cutter can make the difference in quality.

Popular models typically feature advanced optics and robust software. They enable intricate cuts and clean edges. However, not every machine is perfect for every task. Some models may excel in speed but compromise on detail. Others might deliver high precision but fall short in efficiency. Choosing the right machine involves balancing these factors.

Customer feedback highlights the importance of user-friendly interfaces. Having easy access to controls can streamline operations. Equipment durability is another key consideration. Maintenance can be an ongoing challenge. Regular checks are necessary to keep machines running smoothly. Investing time in understanding a specific model is vital for long-term success.

Comparative Analysis of Efficiency in Metal Laser Cutters

When selecting a metal laser cutter, efficiency plays a crucial role. High efficiency means faster cutting without compromising precision. Several factors influence this, including laser power, cutting speed, and material type. It's essential to choose a machine that balances these elements effectively for optimal performance.

**Tip:** Always assess the laser's wattage. Higher wattage may cut thicker materials faster but also consume more energy. This can lead to increased operational costs.

Another important aspect is the cutting path design. A well-optimized path minimizes travel time and maximizes production rates. Poor path design can lead to unnecessary delays. This affects the project's overall efficiency in a significant way.

**Tip:** Consider investing in software that provides advanced path optimization. This tool can help streamline processes and enhance efficiency.

Finally, maintenance cannot be overlooked. Regular checks are vital to ensure the machine runs smoothly. Neglecting maintenance can lead to unexpected downtimes, which can frustrate productivity. How often should you perform these checks? It varies, but consistency is key. Always review the machine’s performance regularly.

Applications of Metal Laser Cutting in Various Industries

Metal laser cutting applications span various industries, from automotive to aerospace. In the automotive sector, precision cutting improves part accuracy. The precision of laser cutting can reduce material waste by up to 30%. Companies often struggle with maintaining efficiency while ensuring precision.

In the aerospace industry, metal cutting technology plays a crucial role. Aerospace parts require extreme accuracy. A report by Grand View Research states that the global metal laser cutting market is expected to reach USD 6.1 billion by 2025. This growth highlights the increasing demand for precise manufacturing processes.

Tips: Focus on proper beam quality. This enhances cutting efficiency. Regular maintenance is essential to keep machines running smoothly. It's also critical to evaluate the material type. Different metals react differently during the cutting process. Understanding these can improve results.

However, challenges arise with thicker materials. Laser penetration can be inconsistent, leading to defects. Operators should consider investing in training. Proper skills can significantly reduce errors. Industry professionals sometimes overlook this vital area, yet it can impact overall productivity.

Related Posts

-

Revolutionizing Precision: How Laser Metal Cutting Machines Transform Industries

-

5 Best Metal Laser Cutter Techniques for Precision Cutting

-

10 Ways Laser Machines Revolutionize Global Manufacturing Efficiency

-

Exploring CO2 Laser Cutter Innovations at the 138th Canton Fair 2025 in China

-

2025 Top 10 Trends in CNC Manufacturing Revolutionizing the Industry

-

Revolutionizing Precision: How CNC Cutting is Transforming Modern Manufacturing Processes