5 Best CNC Turning Techniques to Maximize Precision and Efficiency

CNC turning is a pivotal process in the realm of machining, providing exceptional precision and efficiency that industries across the globe rely on. This advanced technique allows manufacturers to create intricate components with remarkable accuracy, catering to the diverse needs of various sectors including aerospace, automotive, and medical equipment. As technology continues to evolve, enhancing the capabilities of CNC turning, it becomes essential for professionals to stay informed about the best techniques available. In this blog, we will explore the five best CNC turning techniques that can help maximize both precision and efficiency in production. By understanding these methods, manufacturers can not only improve their operational performance but also ensure that they meet the high standards of quality and durability required in today's highly competitive market.

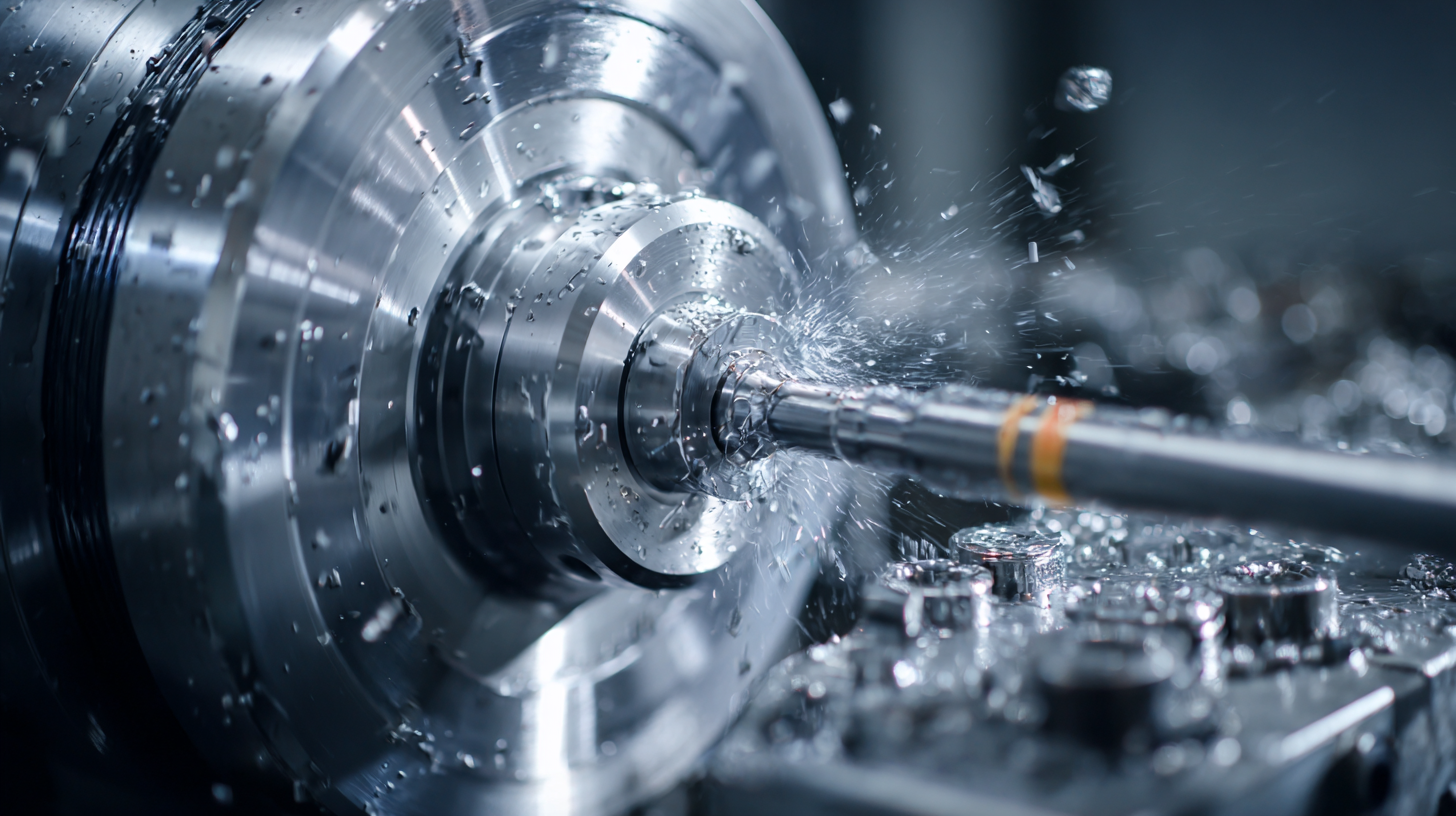

Understanding CNC Turning: An Overview of Techniques

CNC turning is a critical process in modern manufacturing, where precision and efficiency are paramount. Understanding the best techniques for CNC turning can significantly enhance production capabilities. For instance, the implementation of advanced sensing systems in CNC operations allows for real-time monitoring of tool conditions, which can lead to a reduction in tool wear by up to 20% according to a recent review. These sensors utilize imaging and vibration analysis technologies to ensure optimal performance, thereby increasing both precision and operational efficiency during machining.

Furthermore, the integration of machine learning techniques for fault diagnosis has shown promising results. A study highlighted that leveraging three-axis vibration data can improve the accuracy of diagnosing faults in CNC hobbing cutters, thus minimizing downtime and maintenance costs. This novel approach can enhance the production process, enabling manufacturers to maintain higher standards of quality while optimizing resource use. As the industry continues to evolve, staying informed about these innovative techniques will empower companies to maximize their CNC turning capabilities effectively.

Enhancing Precision: Key Factors in CNC Turning Operations

In the realm of CNC turning operations, precision is paramount. Various factors play a critical role in ensuring that these operations achieve optimal accuracy. Key among these is the choice of tooling. Selecting the right material and geometry for tools can significantly influence the finished product's quality. Additionally, tool wear and maintenance directly impact precision; therefore, regular inspections and timely replacements are essential to maintaining accuracy throughout the machining process.

Another vital aspect is the implementation of advanced technologies in CNC turning. The rise of digitalization, IoT, and AI in manufacturing is transforming traditional practices. These technologies facilitate real-time monitoring and adjustments, helping to minimize errors and enhance overall efficiency. By integrating analytical tools, manufacturers can collect valuable data, which can be analyzed to optimize CNC turning parameters further, thereby enhancing precision and productivity in the long run. As the industry continues to evolve, understanding and employing these key factors will be crucial for maximizing precision in CNC turning operations.

Optimizing Efficiency: Best Practices for CNC Turning Processes

CNC turning is a vital manufacturing process that can greatly benefit from efficiency optimization. One of the best practices to enhance productivity is regular maintenance of CNC equipment. Regular checks and calibrations ensure that machines operate at peak performance, reducing downtime and preventing costly errors. By scheduling maintenance at consistent intervals, manufacturers can identify potential issues before they escalate, ensuring that precision remains high throughout the production process.

Another effective strategy is the use of advanced tooling materials. Selecting high-quality cutting tools can significantly improve both the speed and accuracy of CNC turning operations. Carbide and ceramic tools, for example, offer greater durability and can withstand higher temperatures, which reduces wear and tear. Furthermore, implementing adaptive machining techniques, where tools automatically adjust based on real-time feedback, can enhance both efficiency and output quality, allowing for rapid adjustments that account for material variability. Embracing these best practices not only maximizes precision in CNC turning but also fosters a more streamlined and efficient workflow.

Advanced CNC Turning Techniques for Complex Geometries

CNC turning has evolved significantly, allowing machinists to achieve unparalleled precision in the production of complex geometries. Advanced techniques such as multi-axis turning and live tooling capabilities enable the creation of intricate shapes with tight tolerances, which are essential in industries like aerospace and automotive. By incorporating simultaneous movements across multiple axes, these techniques reduce the need for secondary operations, ultimately saving time and enhancing overall efficiency in the manufacturing process.

Another innovative approach is the use of advanced tooling materials and coatings. High-performance carbide tools and specialized coatings can substantially increase tool life and resistance to wear, thereby maintaining consistent performance even under rigorous machining conditions. Additionally, the integration of CAD/CAM software streamlines the design-to-production workflow, enabling artisans to simulate complex geometries before actual machining. This leads to reduced error rates and minimizes material waste, further boosting efficiency in CNC turning applications.

5 Best CNC Turning Techniques to Maximize Precision and Efficiency

This chart illustrates the efficiency and precision of five advanced CNC turning techniques used for complex geometries. The data reflects the average precision percentage and efficiency rating based on industry standards.

Choosing the Right Tools: Essential Equipment for CNC Turning

When it comes to CNC turning, selecting the right tools is imperative for

achieving maximum precision and efficiency. According to a recent report by MarketsandMarkets, the

CNC machine tools market is projected to reach

$100.4 billion by 2026, driven by advancements in technology and increasing adoption in various sectors including

automotive and aerospace. This competitive landscape highlights the necessity for manufacturers to invest in high-quality equipment that enhances operational efficacy.

Essential equipment for CNC turning includes not only the CNC lathe itself but also cutting tools, tool holders, and cam software. High-performance cutting tools, often made from

carbide or high-speed steel, provide better durability and precision, reducing cycle times significantly.

Research from the American National Standards Institute (ANSI) indicates that leveraging the right tool can enhance machining rates by up to

25%. Furthermore, tool holders that allow for quick-change capabilities can reduce downtime and maximize productivity, reinforcing the importance of an integrated

approach to equipment selection in CNC turning processes.

Related Posts

-

Ultimate Guide to Mastering CNC Turning Techniques for Precision Engineering

-

Common Issues Faced in CNC Cutting Operations

-

The Definitive Ultimate Guide to Mastering CNC Cutting Techniques for Precision Fabrication

-

How to Achieve Precision with Aluminum Machining Techniques

-

How to Choose the Right Laser Cutter for Your Business Needs

-

What Makes Metal CNC Machines Essential for Modern Manufacturing