Top 10 Advantages of Sheet Metal Fabrication for Your Projects?

In the modern manufacturing sector, sheet metal fabrication stands out as a cornerstone process. According to a report by Grand View Research, the global sheet metal fabrication market is projected to reach $325 billion by 2027. This growth is driven by its wide applications across industries like aerospace, automotive, and electronics.

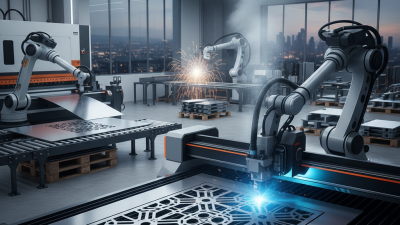

Sheet metal fabrication offers numerous advantages. It provides versatility in design, precision in manufacturing, and cost-effectiveness. For example, laser cutting and CNC machining allow for high accuracy. However, not all projects benefit equally from sheet metal techniques. The choice depends on specific requirements and materials.

Companies must reflect on the reliance on sheet metal fabrication. Are they maximizing its potential? While this process can enhance efficiency and reduce waste, improper implementation may lead to increased costs or delays. Thus, understanding both its benefits and limitations is crucial for successful project outcomes.

Advantages of Sheet Metal Fabrication in Modern Manufacturing

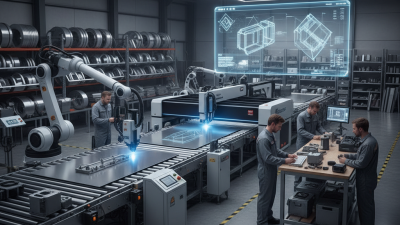

Sheet metal fabrication plays a vital role in modern manufacturing. This technique allows for creating complex shapes while maintaining strength and durability. Precision is key in this process. Using advanced tools, manufacturers can produce intricate designs that enhance product functionality. For example, ventilation systems or components in automobiles often rely on these techniques.

One distinct advantage is the cost-effectiveness of sheet metal fabrication. The materials used are often less expensive than alternatives. Additionally, the fabrication process can be streamlined for mass production. However, there can be limitations. Not all designs translate well into sheet metal. Some require additional modifications, which can increase costs. Each project needs careful consideration to avoid waste.

Flexibility is another benefit. Designers can quickly adapt existing plans to meet changing demands. Whether it’s a custom enclosure or a unique structural element, adjustments are possible. Nevertheless, this flexibility may lead to oversights. Close communication with fabricators is essential to avoid design failures. While efficiencies are gained, overlooking details can be costly down the line.

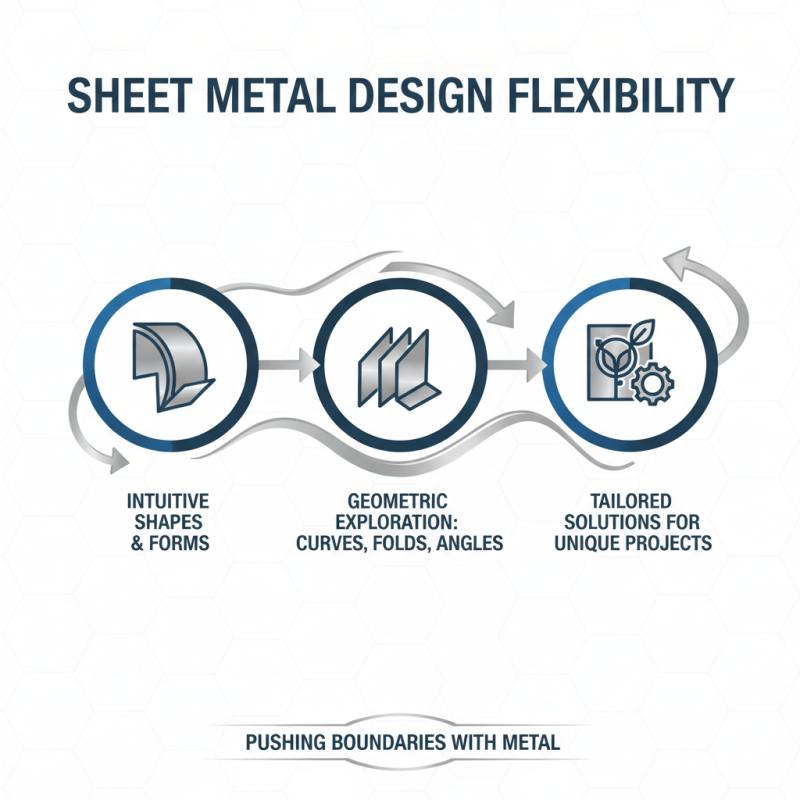

Enhanced Design Flexibility in Fabrication Processes

Sheet metal fabrication offers remarkable design flexibility. This method allows for intricate shapes to be created with relative ease. Designers can push boundaries, experimenting with various geometries. Whether it’s curves, folds, or angles, metal can be manipulated to fit unique project requirements. This versatility leads to tailored solutions that meet specific needs.

Tips: Consider prototyping designs before full production. Small-scale tests can reveal valuable insights. Sometimes, what looks good on paper doesn’t translate well into 3D forms.

Another advantage is the adaptability of materials used in sheet metal fabrication. Steel, aluminum, and copper can all be shaped effectively. Each material brings distinct characteristics, impacting weight and strength. Designers should choose wisely based on the final application. It's important to remember that sometimes the initial choice may not yield the best results. Iteration and refinement are essential in this creative process.

Tips: Keep communication open with your fabrication team. They can provide feedback on material choices and design feasibility. Collaboration can save time and reduce costly errors.

Cost-Effectiveness and Efficiency of Sheet Metal Production

Sheet metal fabrication offers significant cost-effectiveness and efficiency for various projects. According to a report by IBISWorld, the sheet metal fabrication industry has grown by 2.3% annually, indicating rising demand. The use of advanced technologies, like laser cutting, reduces labor costs. This enhances productivity while also minimizing waste.

Moreover, projects utilizing sheet metal can often see a quicker turnaround. Studies show that faster production timelines can lead to an average of 15% savings on project costs. Despite these advantages, companies must consider initial setup expenses, which can be high depending on technology. Yet, the long-term savings often justify these costs.

Operational efficiency also stems from precision in the production process. According to a study by Deloitte, manufacturers improve quality by reducing defects by up to 30% when utilizing modern sheet metal techniques. However, achieving these numbers depends on consistent quality control measures. Companies must invest in training staff to maintain high standards. This is an area with room for improvement for many businesses in the industry.

Improved Durability and Strength of Fabricated Metal Products

Sheet metal fabrication offers significant advantages, particularly in terms of durability and strength. Metal products crafted through this process demonstrate enhanced structural integrity. According to a report by IndustryWeek, fabricated metal products can achieve up to 300% greater strength compared to traditional materials. This is crucial for applications in construction and manufacturing, where reliability is non-negotiable.

In addition to strength, sheet metal is resistant to corrosion and wear. An analysis from the National Association of Manufacturers highlights that aluminum and stainless steel, commonly used in fabrication, provide longer lifespans due to these properties. Projects that prioritize durability often reduce maintenance costs. However, the initial investment in high-quality materials may deter some decision-makers.

Despite the benefits, challenges exist. Not all fabricators have the same capabilities, leading to variations in product quality. Often, simpler designs may overlook critical strength factors. Additionally, cost pressures can force compromises in material selection. A balance is essential. Focusing solely on price can hinder long-term performance. A thoughtful approach is needed to maximize the benefits of sheet metal fabrication.

Environmental Benefits of Using Sheet Metal in Projects

Sheet metal fabrication offers significant environmental advantages that make it a preferred choice for many projects. One of the most notable benefits is its recyclability. According to a report by the American Institute of Steel Construction, steel, a common sheet metal material, can be recycled without any degradation in quality. This means that once a product reaches the end of its life, it can be repurposed into new products, significantly reducing waste.

Energy efficiency is another critical factor. Studies show that manufacturing with sheet metal can be less energy-intensive compared to other materials like plastics. The metal forming process typically generates less waste, as parts can be cut more precisely. However, it’s important to consider the impacts of the metals extraction process, which can be environmentally taxing. As the industry moves towards greener practices, the focus should shift to sustainable sourcing of raw materials.

Furthermore, sheet metal's durability leads to a longer lifespan for products. This longevity reduces the frequency of replacements, ultimately minimizing resource consumption. Yet, not all sheet metal products are created equally. Some may involve coatings or treatments that aren’t eco-friendly. It's essential to be discerning about the processes used in fabrication to maximize the environmental benefits of sheet metal. Balancing functionality with eco-conscious choices is essential for more sustainable construction practices.

Top 10 Advantages of Sheet Metal Fabrication

Related Posts

-

Top 10 Best Sheet Metal Fabrication Techniques for Your Industry Needs

-

The Future of Sheet Metal in 2025 Trends Innovations and Best Practices

-

How to Start Sheet Metal Fabrication in 2026?

-

10 Ways Laser Machines Revolutionize Global Manufacturing Efficiency

-

How to Choose the Right Laser Cutter for Your Business Needs

-

Ultimate Guide to Choosing the Right Laser Metal Cutting Machine for Your Business Needs